Что такое быстрое прототипирование?

Чтобы сохранить и увеличить конкурентоспособность, производители стремятся выводить продукцию на рынок в минимальные сроки. Как достичь этой цели? Один из способов – сократить цикл разработки продукта.

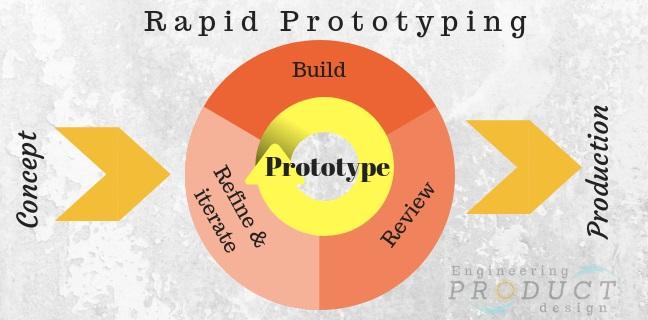

Прототипирование, будучи ключевым этапом разработки, – процесс достаточно трудоемкий: чтобы понять, какое решение будет наиболее эффективным, потребуется длительный этап проектирования и доработок с выполнением ряда итераций.

Для достижения наилучших результатов эту стадию нужно завершать как можно раньше. Быстрое прототипирование, то есть создание прототипов посредством 3D-печати, позволяет существенно сократить цикл разработки и сэкономить ресурсы.

3D-технологии помогают сократить весь процесс, начиная с формулировки идеи до создания физического объекта, до нескольких часов. Быстрое прототипирование дает возможность улучшить и экономические показатели: экономится не только время на разработку, но и трудовые затраты.

(pdf) rapid prototyping and manufacturing: a review of current technologies

12 Copyright © 2009 by ASME

This process was developed for fabrication of metallic parts

from foils. The process uses a high frequency ultrasonic

energy source to induce combined static and oscillating shear

forces within metal foils to produce solid-state bonds and

build up a near-net shape part, which is then machined to its

final dimensions using an integrated, three-axis CNC milling

machine. UC combines the advantages of additive and

subtractive fabrication approaches allowing complex parts to

be formed with high-dimensional accuracy and surface finish,

including objects with complex internal passageways, objects

made up of multiple materials, and objects integrated with

wiring, fiber optics, sensors, and instruments, [41].

5 CONCLUSION

RP&M technologies have considerably evolved from their

origin, more than 25 years ago. Several new RP&M systems

have been proposed during these years. RP&M research has

been focused on the development of systems to support new

materials, e.g. organism processes, systems to support micro

and nano fabrication, systems to fabricate end-user parts,

systems based on new fabrication methods, and systems

combining different RP&M techniques. Although there are

many new proposed systems, few of them are commercially

available; most of them are in development or have been

proposed without commercial success. However, the original

goal still remains as a key factor; reduce design and

manufacturing costs and leads times to increase

competitiveness.

ACKNOWLEDGMENTS

The first author would like to thank the PROMEP

program from SEP in Mexico for the support provided to this

project.

REFERENCES

[1]Editorial, 2002, “Rapid technologies: solutions for today

and tomorrow”, Computer-Aided Design, Vol. 34, pp.

679-682, Elsevier.

[2]Yan Xue, Gu P., A Review of rapid prototyping

technologies and systems, Computer-Aided Design, Vol.

28, No. 4, pp. 307-318, 1996.

[3]Pham D.T., Gault R.S., A comparison of rapid

prototyping technologies, International Journal of

Machine Tools & Manufacture, 38, pp. 1257-1287, 1998.

[4]Karapatis N.P., van Griethuysen, GlardonR., Direct rapid

tooling: a review of current research, Rapid prototyping

journal, 4, 2, pp. 77-89, 1998.

[5]Upcraft Steve, Fletcher Richard, The rapid prototyping

technologies, Assembly automation, 23, 4, pp. 318-330,

2003.

[6]Medellin H., Lim T., Corney J., Ritchie J.M., Davies

J.B.C., Automatic subdivision and refinement of large

components for rapid prototyping production, Journal of

Computing and Information Science in Engineering, Vol.

7, No. 3, pp. 249-258, 2007.

[7]Dutta D., Brinz F.B., Rosen D., Weiss L., Layer

manufacturing: current status and future trends, Journal

of Computing and Information Science in Engineering,

Vol. 1, No. 1, pp. 60-71, 2001.

[8]Steve Upcraft and Richard Fletcher, The rapid

prototyping Technologies, Assembly Automation,

Volume 23, Number 4, pp. 318–330, 2003

[9]Behrokh Khoshnevis, Melanie P. Bodiford, Kevin H.

Burks, Ed Ethridge, and Dennis Tucker, Won Kim,

Houssam Toutanji, Michael R. Fiske, Lunar Contour

Crafting – A Novel Technique for ISRUBased Habitat

Development, American Institute of Aeronautics and

Astronautics Conference, pp. 1-12, 2005.

[10]Yong-Ak Songa, Sehyung Park, Doosun Choi, Haesung

Jee, 3D welding and milling: Part I–a direct approach for

freeform fabrication of metallic prototypes, International

Journal of Machine Tools & Manufacture 45, pp. 1057–

1062, 2005

[11]

Zhongzhong Chen, Dichen Li, Bingheng Lu, Yiping

Tang, Minglin Sun and Zhen Wang, Fabrication of

artificial bioactive bone using rapid prototyping, Rapid

Prototyping Journal Volume 10 · Number 5, pp. 327–

333, 2004

[12]Sanjay B. Joshi, Richard A. Wysk, Matthew Frank,

CNC-RP: A Technique for Using CNC Machining as a

Rapid Prototyping Tool in Product/Process

Development, Department of Industrial and

Manufacturing Engineering, The Pennsylvania State

University, pp. 1-5, 2002.

[13]Cong Bang Pham, Kah Fai Leong, Tze Chiun Lim and

Kerm Sin Chian, Rapid freeze prototyping technique in

bio-plotters for tissue scaffold fabrication, Rapid

Prototyping Journal 14/4, pp.246–253, 2008

[14]Yan, Y., Wu, R. and Zhang, Biomaterial forming

research using RP technology, Rapid Prototyping

Journal, Vol. 9, pp. 142-9. 2003

[15]Zhuo Xiong, Yongnian Yan, Renji Zhang and Xiaohong

Wang, Organism manufacturing engineering based on

rapid prototyping principles, Rapid Prototyping Journal,

11/3, pp.160–166, 2005

[16]Mironv, V., Boland, T. and Trusk, T., Organ

printing:computer-aided jet-based 3D tissue engineering,

Trends in Biotechnology, Vol. 21 , pp. 157-218, 2003

[17]Xiong, Z., Yan, Y.N., Wang, S., Zhang, R. and Zhang,

C., Fabrication of porous scaffolds for bone tissue

engineering via low-temperature deposition, Scripta

Materialia, Vol. 1, pp. 771-777.2002

[18]N. Hopkinson, R.J.M. Hague and P.M. Dickens, Rapid

Manufacturing An Industrial Revolution for the Digital

Age, John Wiley & Sons,Vol. 1, pp. 55-79, 2006.

[19]D.T. Pham, R.S. Gault, A comparison of rapid

prototyping technologies, International Journal of

Machine Tool & Manufacture 38, Vol 1, pp.1257-1287,

1998.

[20]T. Hanemann, W. Bauer, R. Knitter, and P. Woias, Rapid

Prototyping and Rapid Tooling Techniques for the

Manufacturing of Silicon, Polymer, Metal and Ceramic

Microdevices, 1Forschungszentrum Karlsruhe, Institut f.

Materialforschung III,vol.1, pp. 187-218,

[21]Frank Liou, Kevin Slattery, Mary Kinsella, Wright-

Patterson, Joseph Newkirk, Hsin-Nan Chou, Robert

Landers, Applications of a hybrid manufacturing process

for fabrication of metallic structures, Rapid Prototyping

Journal 13/4, pp. 236–244, 2007.

§

(pdf) rapid prototyping journal

patient-specific temporomandibular joint implant”,

Computer Methods in Biomechanics and Biomedical

Engineering, Vol. 15 No. 4, pp. 363-370.

Garcia, M. (2009), “Surgical treatment of interphalangeal

joint arthritis”, Medscape, 30 September.

Giannatsis, J. and Dedoussis, V. (2009), “Additive fabrication

technologies applied to medicine and health care: a review”,

International Journal of Advanced Manufacturing Technology,

Vol. 40 Nos 1/2, pp. 116-127.

Hilker, A., Miehlke, R.-K. and Schmidt, K. (2007),

“Prosthetics of metacarpophalangeal joints”, Z Rheumatol,

Vol. 66 No. 5, pp. 366-375.

Hogan, C.J. and Nunley, J.A. (2006), “Post traumatic

proximal interphalangeal joint flexion contractures”,

Journal of the American Academy of Orthopaedic Surgeons,

Vol. 14 No. 9, pp. 524-533.

Knahr, K. (2020), “Total hip arthroplasty”, Effort Reference in

Orthopaedics and Traumatology, Springer, pp. 4-22.

Klarlund, M., Ostergaard, M., Jensen, K., Madsen, J., Skjodt,

H. and the TIRA group (2000), “Magnetic resonance

imaging, radiography, and scintigraphy of the finger joints:

one year follow up of patients with early arthritis”, Annals of

the Rheumatic Diseases, Vol. 59 No. 7, pp. 521-528.

Margareta, N. and Frankel, V.H. (2020), Basic Biomechanics

Of The Musculoskeletal System, 4th ed., Wolters Kluwer/

Lippincott Williams & Wilkins, Philadelphia, PA.

Materialise (2020), “Biomedical software and solutions for

engineering on Anatomy”, available at: http://biomedical.

materialise.com/mimics

MedicineNet (2020), “Rheumatoid Arthritis (RA)”, available

at: www.medicinenet.come/rheumatoid_arthritis/article.

htm

Murr, L.E., Gaytan, S.M., Martinez, E., Medina, F. and

Wicker, R.B. (2020), “Next generation orthopaedic

implants by additive manufacturing using electron beam

melting”, International Journal of Biomaterials, Vol. 2 No. 3,

pp. 1-14.

Stewart, N., McQueen, F. and Crabbe, J. (2001), “MRI of the

wrist: a pictorial essay”, Australasian Radiology, Vol. 45

No. 3, pp. 268-273.

Thomsen, P., Malmström, J., Emanuelsson, L., Rene, M. and

Snis, A. (2009), “Electron beam-melted, free-form-

fabricated titanium alloy implants: material surface

characterization and early bone response in rabbits”,

Journal of Biomedical Materials Research Part B: Applied

Biomaterials, Vol. 90 No. 1, pp. 35-44.

Palmquist, A., Lindberg, F., Emanuelsson, L., Brånemark,

R., Engqvist, H. and Thomsen, P. (2020), “Biomechanical,

histological and ultrastructural analyses of laser micro- and

nano-structured titanium alloy implants: a study in rabbit”,

Journal of Biomedical Materials Research, Vol. 92A No. 4,

pp. 1476-1486.

Parthasarathy, J. (2009), Design, Analysis, and Fabrication of

Porous Titanium Implants Using Electron Beam Melting for

Craniofacial Applications, PhD Dissertation, University of

Oklahoma, Norman.

Peck, J.N. (2020), “Weight-bearing surfaces”, in Peck, J.N.

and Marcellin-Little, D.J. (Eds), Advances in Small Animal

Total Joint Replacement, John Wiley & Sons, West Sussex.

Takigawa, S., Meletiou, S., Sauerbier, M. and Cooney, W.P.

(2004), “Long-term assessment of Swanson implant

arthroplasty in the proximal interphalangeal joint of the

hand”, The Journal of Hand Surgery, Vol. 29 No. 5,

pp. 785-795.

Steven, K. (2004), The UHMWPE Handbook: Ultra-High

Molecular Weight Polyethylene in Total Joint Replacement,

1st ed., Elsevier Academic Press, San Diego, CA.

Further reading

Herren, D.B., Schindele, S., Golden, J. and Simon, B.R.

(2006), “Problematic bone fixation with pyrocarbon

implants in proximal interphalangeal joint replacement:

short-term results”, Journal of Hand Surgery (British and

European Volume), Vol. 31 No. 6, pp. 643-651.

Swanson, A.B. (1972), “Flexible implant arthroplasty for

arthritic finger joints rationale, technique, and results of

treatment”, The Journal of Bone & Joint Surgery, Vol. 54

No. 3, pp. 435-544.

Corresponding author

Emad Abouel Nasr can be contacted at: eabdelghany@ksu.

edu.sa

For instructions on how to order reprints of this article, please visit our website:

www.emeraldgrouppublishing.com/licensing/reprints.htm

Or contact us for further details: permissions@emeraldinsight.com

Rapid prototyping technique

Emad Abouel Nasr et al.

Rapid Prototyping Journal

Volume 21 · Number 4 · 2020 · 449–460

460

Downloaded by Mr Abdulsalam Altamimi At 09:12 08 August 2020 (PT)

§

(pdf) rapid prototyping technology and its applications

SUMMARY

This paperprovidesanoverviewof RPtechnologyin briefandemphasizesontheir abilityto

shorten the product design and developmentprocess. Classification of RP processes and details

of fewimportantprocessesis given.Thedescription ofvariousstagesof datapreparationand

model building has been presented. An attempt has been made to include some important factors

tobe consideredbefore startingpart deposition forproper utilizationof potentials ofRP

processes.

REFERENCES

•Chua, C.K., Leong, K.F. (2000) Rapid Prototyping: Principles andApplications in

Manufacturing, World Scientific.

•Gebhardt, A., (2003) Rapid Prototyping, Hanser Gardner Publications, Inc., Cincinnati.

•Pandey, P.M., Reddy N.V., Dhande, S.G. (2003a) Slicing Procedures in Layered

Manufacturing: A Review, Rapid Prototyping Journal, 9(5), pp. 274-288.

•Pandey, P.M., Reddy, N.V., Dhande, S.G. (2003b) Real Time Adaptive Slicing for Fused

Deposition Modelling, InternationalJournal of MachineTools and Manufacture,43(1),

pp 61-71.

•Pandey, P.M., Reddy, N.V., Dhande, S.G. (2004a) Part Deposition Orientation Studies in

LayeredManufacturing,ProceedingofInternationalConferenceonAdvanced

Manufacturing Technology, pp. 907-912.

•Pandey, P.M., Thrimurthullu, K., Reddy, N.V. (2004b) Optimal Part Deposition

Orientation in FDM using Multi-Criteria GA, International Journal of Production

Research, 42(19), pp. 4069-4089.

•Thrimurthullu, K.,Pandey, P.M.,Reddy,N.V. (2004)PartDepositionOrientationin

FusedDepositionModeling,InternationalJournalofMachineTools andManufacture,

2004, 44, pp. 585-594.

•Williams, R.E., Komaragiri., S.N., Melton, V.L., Bishu, R.R. (1996) Investigation ofthe

Effect ofVariousBuildMethods onthePerformance ofRapidPrototyping

(Stereolithography), Journal of Materials Processing Technology, 61, (1-2), pp. 173-178.

§

(pdf) rapid prototyping technology: applications and benefits for rapid product development

9.Conclusion

Sweepingchangesinmanufacturingpracticeshave

takenplaceintheEightiesandacceleratewithadded

momentum in the Nineties.Shorter product life cycle,

betterqualityandreliability,andeliminationof

wasteshavebecomeindustrystandards.More

importantly,greateremphasisisnowputonnew

productdevelopmentandtime-to-market.Without

doubts, products withoutstanding quality, satisfying a

marketniche,arepre-requisitesforasuccessful

company.

Veryfewtechnologieshaveofferedasmuchas

RPTinthelastfewyears.Componentscannowbe

producedinafractionofthetimethatwasrequired

previouslywiththeaddedbene®tsofreducedcosts

andmoredesigniterations.Designershavebeen

releasedfromold constraints withnewtoolsfromthe

arrayRPT.Managersmusttakeonnewbusiness

practices,designersmustunderstandthepowerat

their®ngertips,processengineersneedknowofthe

newprocessroutesandmarketingpersonnelmustbe

awareoftheirnewfoundabilitytoreactquicklyto

market changes.The global marketplace isimpatient,

price-sensitive,andintolerant ofcarelessness.Weare

requiredtomoveswiftly,bothtoeliminatecoststhat

donot addvalue and todeliver unprecedentedquality.

Thesearethenewrulesofsurvival.

References

Burns,M.(1993)AutomatedFabricationÐImproving

productivityinmanufacturing,1stedition.PTR

PrenticeHall,NewJersey.

Charney, C.(1990)TimetoMarket:Reducing Product lead

time,SocietyofManufacturingEngineers,Dearborn,

MI.

EARP.(1995a)Why?When?How?TouseRPTinthe

productdevelopmentprocess,AGuidefromEARPÐ

EuropeanActiononRapidPrototyping,Brite/Euram

BE-6075R&DProject.

EARP.(1995b)SpecialMedicalEdition.EARPÐ

NewsletterNo.5,Ed.BentMieritz,Danish

TechnologicalInstitute,AarhusC,Denmark.

Halliday,I. (1995)Gettingthe BusinessBene®ts fromRapid

Prototyping. Proc.4th EuropeanConference on Rapid

PrototypingandManufacturing,pp.297±306.

Iuliano, L.,Gatto, A.and DeFillipi,A.(1995)Metallization

and Rapid Tooling. Proc. 4thEuropean Conference on

RapidPrototypingandManufacturing,pp.261±277.

Jacobs,P.F.(1992)RapidPrototypingandManufacturing:

FundamentalsofStereolithography,1stedition,

SocietyofManufacturingEngineers.Dearborn.

Jacobs,P.F.(1993)Stereolithography1993:EpoxyResins

ImprovedAccuracy andInvestment Casting.Proc. 2nd

EuropeanConferenceonRapidPrototyping&

Manufacturing,pp.95±111.

Jacobs,P.F.(1995),QuickCast

TM

1.1&RapidTooling.

Proc.4thEuropeanConferenceonRapidPrototyping

andManufacturing,pp.1±25.

Jensen,K.L.(1993)InstantMedicoModels.EARPÐ

NewsletterNo.2,Ed.BentMieritz,Danish

TechnologicalInstitute,AarhusC,Denmark.

Josip,S.(1994)StereolithographyBasedOperation

PlanninginMaxillofacialReconstructionSurgery.

EARPÐNewsletterNo.3,Ed.BentMieritz,Danish

TechnologicalInstitute,AarhusC,Denmark.

Luck,T., Baumann,T.andBaraldi,U.(1995)Comparison of

DownstreamTechniquesforFunctionalandTechnical

PrototypesÐFast Tooling with RP. Proc. 4thEuropean

ConferenceonRapidPrototypingandManufacturing,

pp.247±261.

McAloon,K.,McLean,C.andVancrean, W.(1993)Report

fromtheInternationalWorkshoponStereolithography

inMedicine.EARPÐNewsletter),No.2,Ed.Bent

Mieritz,DanishTechnologicalInstitute,AarhusC,

Denmark.

McAloon,K.(1994)ReportfromtheInternational

WorkshoponStereolithographyinMedicine.EARPÐ

Newsletter,No.3,Ed.BentMieritz,Danish

TechnologicalInstitute,AarhusC,Denmark.

Murphy,M.L.(1995)RapidPrototypingByLaserSurface

Cladding,PhDThesis,UniversityofLiverpool.

Onuh,S.O.(1996)AnExperimentalStudyon

StereolithographyProductQuality,PhDThesis,

UniversityofLiverpool.

Prioleau,F.R.(1991)ApplicationsofStereolithographyin

InvestmentCasting,Proc.2ndInternational

ConferenceonRapidPrototyping,Dayton,Ohio.

1991,pp.149±151.

Suh,Y.S.andWozny,M.J.(1994)AdaptiveSlicingof

SolidFreeformFabricationProcesses.Proc.Solid

FreeformFabricationSymposium,Austin,USA,

pp.404±411.

Thompson,G. A.and Pridham,M. S.(1995) LaserForming.

Proc.4thEuropeanConferenceonRapidPrototyping

andManufacturing,pp.137±147.

Tromans,G.andWimpenny,D.(1995)Rapid

Manufacturing.Proc.4thEuropeanConferenceon

RapidPrototypingandManufacturing,pp.27±41.

Rapidprototypingtechnology

311

§

Advantages and disadvantages of rapid prototyping

Like any manufacturing process or design stage, prototyping and rapid prototyping have their own pros and cons.

Fidelity types

Is rapid prototyping the same as 3d printing?

The simple answer is “No”. In modern-day product development process, rapid prototyping is commonly used alongside terms like “3D printing” and “additive manufacturing” mainly because 3D printing first came into prominence as a way of making prototypes quickly (Read more on the history of 3D printing).

But the 7 types of additive manufacturing technologies have moved along and have made giant strides towards the production of quality parts and might not be the preferred choice for some prototypes due to higher costs.So, what is the difference between rapid prototyping and 3D printing?

Npd stage types

In modern-day engineering product design, prototyping process of build, review and refine, fits into all four major stages of the design process (product planning, conceptual design, embodiment design and detailed design).

- Proof of concept prototypes

- Demonstration or presentation model prototypes

- Functional prototypes

- Aesthetic or industrial design prototypes

- Final factory sample

- Alpha & beta build prototypes

Types of prototypes in product design

Prototypes can be categorised depending on the degree of accuracy required i.e. “Fidelity” or where in the product development stage it is used.

Types of rapid prototyping techniques

Choosing the right rapid prototyping technology is critical to the success of a prototype. Each rapid prototyping technique has its own compromise in terms of cost, speed, material compatibility of the feature, fidelity level and development stage.

Rapid prototyping doesn’t need to be limited to one process, one can use more than one manufacturing techniques to assemble a prototype.

Following are the types of rapid prototyping technology available for engineering product designers:

What is rapid prototyping?

Rapid prototype or rapid prototyping is a relatively new term and in its simplest form, the process of creating prototypes quickly to visually and functionally evaluate an engineering product design.

Careful consideration of the 5 key factors, viz. purpose, quality, quantity, complexity and cost would have a major impact on the prototyping success.

Why is rapid prototyping important?

In this fast-moving modern-day consumer market, companies need to develop and introduce new products faster to remain competitive. Since faster product development and technology innovation are key to a company’s success, rapid prototyping becomes the most important element of new product development. The following objectives are achieved through rapid prototyping.

Задачи и сферы применения

3D-печать прототипов позволяет оптимизировать выполнение таких задач, как проектирование и модернизация модели, проверка на собираемость, визуальное представление детали или проекта, макетирование и тестирование для более оперативного запуска новых моделей.

С помощью 3D-принтера отдельно решается задача создания прототипов при изготовлении корпусов различных изделий для проверки на собираемость и функционального тестирования. Также возможна 3D-печать готовых корпусных изделий для применения на производстве.

Технология быстрого прототипирования применяется в следующих областях:

Быстрое прототипирование используется для изготовления как наглядных моделей, которые служат для визуализации идеи продукта и дают возможность оценить и усовершенствовать дизайн, так и функциональных прототипов, позволяющих ускорить реверс-инжиниринг и изготовление деталей, снятых с производства.

С помощью 3D-принтера можно быстро и экономично печатать прототипы обоих видов. 3D-печать помогает оперативно получить прототип с оригинала изделия или с CAD-модели. Точность печати обеспечивает максимальное соответствие изделий данным САПР, что обеспечивает высокое качество печати.

Благодаря многообразию термопластиков, композитов, полимеров, фотополимеров и других инновационных материалов для 3D-печати пользователь сможет создать изделие именно с теми физико-механическими свойствами и внешним видом, которые необходимы для решения конкретных задач.

Какие технологии и оборудование используются для 3d-печати прототипов

Для решения задач быстрого прототипирования в основном применяются следующие аддитивные технологии:

Наша компания предлагает широкий выбор оборудования для 3D-печати прототипов от ведущих производителей:

Примеры быстрого прототипирования

Задача: прототипирование компонентов гоночных мотоциклов с целью улучшить конструкцию, аэродинамику, а также комфорт гонщиков при подготовке к чемпионату мира MotoGP.

Итоги: кратко

Время – самый дефицитный ресурс современного предприятия. Сэкономить время на изготовление и оценку физической модели продукта, сократить процесс разработки и воспользоваться изменениями на рынке для приобретения клиентов поможет быстрое прототипирование с использованием 3D-печати.

Широкие возможности аддитивных технологий и большой выбор оборудования и расходных материалов позволяют найти подходящее решение в самых разных областях применения и получить высокоточные и прочные модели в кратчайшие сроки.

Опытные эксперты компании iQB Technologies проконсультируют вас по вопросам, связанным с внедрением 3D-технологий, и предложат готовые 3D-решения для вашего предприятия, НИИ или вуза.