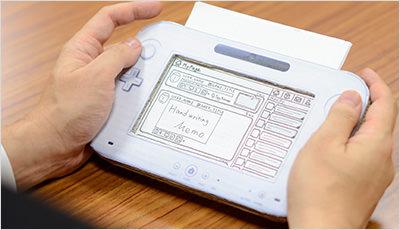

Paper Prototyping

Mungkin kalian menduga, kalau Paper Prototype itu terbuat dari hasil screenshoot dari layar kemudian di cetak di atas kertas. itu ada benarnya juga, akan tetapi metode ini memiliki tingkat kompleksitas yang berbeda. Memang benar Paper Prototype berbentuk sketsa, konsep, gambar atau storyboard, yang mewakili kerangka interface pengguna kalian. Tapi eksekusinya lebih pada gambar coretan dengan tangan dan marker.

Yang pasti Paper prototyping bukan merupakan pengganti sepenuhnya dari digital prototyping. Tujuan dari metode ini untuk mengumpulkan feedback dengan cepat dari pengguna dan memastikan tim kalian yang berada dalam proyek berada di jalur yang benar sejak hari pertama.

Kapan menggunakan metode ini?Paper prototyping sangat cocok untuk konseptualisasi tahap awal. Kecepatan, kemudahan, dan kesederhanaannya, belum lagi dokumentasi otomatis, membuatnya jauh lebih cocok untuk bereksperimen dengan ide-ide baru daripada prototipe digital yang lebih kompleks.

Tools untuk membuat Paper Prototyping?Beberapa tools untuk membuat paper prototyping yang pasti paper and marker kalau mau instant gunakan printer, print free template ui kit bisa juga jadi alternatif.Sebagai contoh toolsnya bisa klik link berikut.

Akan tetapi, saya hampir tidak pernah menggunakan metode ini seutuhnya, ya karena sekarang banyak tools online digital prototyping yang sangat mudah, dan juga metode ini memiliki berbagai kekurangan. Apa saja keuntungan dan kekurangannya? yuk kita bahas di bawah ini.

3d printers as rapid prototyping tools | zortrax

R&D staff can iterate through different designs rapidly which make their work more efficient.

Prototypes are made entirely in-house which contributes to better intellectual property protection.

Fast and efficient prototyping stage leads to shorter time to market, so a new product can bring in revenue sooner.

3D printing is capable of producing shapes impossible to make with traditional manufacturing techniques.

Binder jet 3d printing

Another rapid prototyping and additive manufacturing technology.

Here, an inkjet print head deposits liquid binding material onto the last layer of the part. After it’s done, a new layer is formed by spreading powder material onto the binding liquid. As it solidifies, it forms another layer.

The biggest problem with this kind of rapid prototyping technology is wasting of the powder material. While some of the excess material can be reused, there are limitations to the number of times it can be done.

Also, some of the excess material has to be thrown away right after the first manufacturing cycle is complete.

Clean and safe 3d printer rapid prototyping —

Mechanization of any production plant helps increase the output. The high-quality 3d printer rapid prototyping on shkoda-avto.ru help assemble working machines better for greater efficiency. These products are original with secure factory properties, and so they will fit better as replacements in case of any breakdowns. The durable 3d printer rapid prototyping are made from high-quality materials to last longer. Furthermore, these products are food-grade and are hygienically safe for the making of food items.

With better operations, the 3d printer rapid prototyping on shkoda-avto.ru are more productive, churning out steady consistent streams of goods. After proper assembly, the components work seamlessly with other sections. Users will have fewer repair costs to worry about as there are little to no damages encountered. The results of the operations are healthier and higher-quality foodstuffs.

When trying to secure any 3d printer rapid prototyping, buyers should concentrate on safety measures first. Again, the capacity to deliver the said results is crucial. The robustness of the products is essential as mechanical parts wear and tear periodically. The replacement gadgets should be as efficient as the original ones. In case of breakdowns, buyers need to replace the bits fast for sustainable operations.

The reliable sellers on shkoda-avto.ru with verifiable reviews help buyers settle on the desired purchase doubtlessly. Browse their informative catalogs, which provide better insight into what the market offers, for competitive deals on 3d printer rapid prototyping. Most importantly, global suppliers online have a variety of ready-to-ship samples and goods for their customers.

Communicate ideas

Physical models convey ideas to collaborators, clients and marketers in ways computer models can’t. Rapid prototyping facilitates the clear, detailed feedback essential to product success, and lets designers quickly respond to input.

Communication of ideas

To be fair, CAD software itself already took a great leap forward from engineering drawings. You can change the part design with a few clicks, rotate it, find assembly interferences and move the assembly as you like. But it is not the same as real life..

Actually touching and playing around with a product still in the concept phase can clearly bring forth the shortcomings and spark some more inspiration. Also, others will be able to see your vision in action.

Sometimes, such visualisation may also be a deal-maker when pitching a solution to a customer or an investor.

Complex parts

We will get to the technology shortly. But it is important to consider that most of the production methods revolve around 3D printing and CNC machining. Although we are talking about prototyping, these same methods can later be used for full-scale manufacturing.

One of the great perks here is the flexibility of these production technologies. They are able to create very intricate parts, including ones that stem the features from generative design methods. This advanced CAD feature lets engineers optimise the parts for material use and cost, which may come in especially handy in industries like automotive and aerospace.

Digital light processing (dlp)

Similarly to stereolithography (SLA), digital light processing is a 3D printing method that utilises a photopolymer resin which solidifies under a light source.

The most significant difference comes in speed. DLP lasers cure a whole layer at a time while SLA does so point by point. At the same time, curved surfaces may have a rougher texture and quality compared to SLA.

Fidelity types

Fused deposition modelling (fdm)

Also known as fused filament fabrication, this is the most common form of 3D printing. The majority of hobbyists looking to produce their prototyping design concepts use this type of rapid prototyper machines.

It uses a continuous thermoplastic filament to create the parts. During the process, the filament is heated at the nozzle or extruder head.

CNC-controlled motors move the head during printing according to the input. The surface finish of the parts is not as good as with many of the other processes, but the popularity of the method stems from its affordability.

3D printed objects created by fused deposition modelling may also require support structures in the case of a more complex design with overarching features. These are usually removed during post-processing.

How to incorporate rapid prototyping ideas during the design phase?

If possible, the test product can be simplified for cost-effective production. For example, a test product may replace tapped holes with regular holes as it is easier to produce but does not, in some cases, affect the functionality of the part.

Laminated object manufacturing

Laminated object manufacturing, or LOM for short, uses thermoplastic adhesives when stacking layers of sheet material on top of each other.

The sheet material has to reach certain temperatures first to activate the adhesive on top of the last layer. For that reason, a heated roller is placed just before the stack that ends up as the rapid proto part.

As soon as the new layer is in place, a laser beam cuts it into shape.

Npd stage types

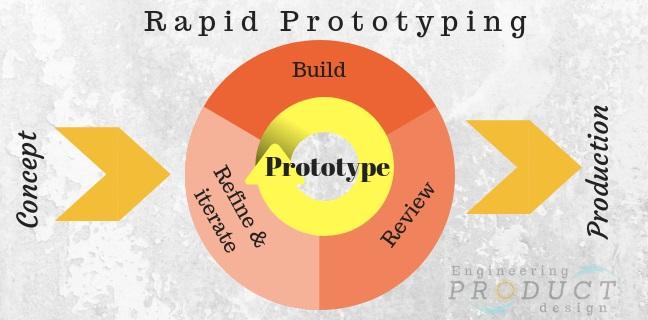

In modern-day engineering product design, prototyping process of build, review and refine, fits into all four major stages of the design process (product planning, conceptual design, embodiment design and detailed design).

- Proof of concept prototypes

- Demonstration or presentation model prototypes

- Functional prototypes

- Aesthetic or industrial design prototypes

- Final factory sample

- Alpha & beta build prototypes

Online cnc machining

Now we come to the more traditional manufacturing methods. CNC machining is well suitable for prototyping parts from a variety of different materials, from metals to plastics.

Online sheet metal fabrication

Sheet metal fabrication has also moved online by now. While CNC machining may need a lot of setups over the course of producing a single part, laser cutting and bending a uniform thickness sheet is a little less complicated.

Online service providers often feed large datasets from manufacturing partners to the algorithms to arrive at reasonable market prices.

Sheet metal prototyping is a great way to aid the product development process by building the design as intended. This means you can make the parts with complex cutouts from the chosen material (e.g. S355 instead of a cardboard substitute) to also test the parts for the structural qualities in an assembly.

Price

The availability of these services online means that you do not have to spend time to produce the parts yourself while also minimising the activities related to outsourcing production.

In case of 3D printing, it is even viable to purchase a printer for in-house use because of the simultaneous advancements in technology and drop in machinery costs.

The automated nature of the whole manufacturing process also lowers the adjacent costs related to operating the machinery.

Quickness

Need the parts in under a week? No problem.

Small 3D printed parts can easily be created in a few hours. Here, the new process has significantly reduced the time spent on actual manufacturing.

In the case of CNC machining and laser cutting, the level of automation has had a great effect on overall speed and costs. The ability to process CAD files for automated pricing, machine setups and creating cutting programs is the driving force behind that change.

So whichever service you are going for, expecting the parts in less than a week is reasonable. This can definitely speed up the whole product-to-market cycle.

Rapid prototyping machines | roland dga

Acrylic, acetal, nylon and ABS are quickly and easily milled with Roland DG desktop and

benchtop milling machines

. Mill precision fan parts, gears, bearing blocks, tools and thousands more items for accurate proof of concepts. With hundreds of plastics to choose from, you can create limited edition toys, product prototypes, industrial prototypes, electrical parts and casings, models and so much more.

Rapid prototyping technology

We’ll start by pinpointing all the different additive manufacturing methods and then continue with more traditional ones like CNC machining and laser cutting, showing exactly how they can be used for rapid prototyping.

Selective laser melting (slm)

In essence, very similar to selective laser sintering (SLS). The main difference is in the materials – SLM, or direct metal laser sintering (DMLS) is suitable for metals.

Also, SLS does not need as high temperature for fusing the materials, whereas SLM actually needs the metal to melt in order to form stable bonds and a homogenous part.

Selective laser sintering (sls)

Also an additive manufacturing technology, selective laser sintering uses material powder and a high power laser to create the final part.

The laser beam heats the material to fuse the particles of plastic, glass, ceramic, etc. into a solid object with the desired shape. It also works on a layer-by-layer basis. After printing a layer, more material (about 0.1 mm) is added to form the next layer.

The SLS machine uses a pulsed laser because the density of the part depends on peak power output. The mass of powder is always in a heated state just below the fusing point.

One of the perks of using laser sintering is that there is no necessity for extra support. The part is always surrounded by loose material particles which secure the position and shape.

Stereolithography (sla)

A form of 3D printing technology that manufactures parts layer by layer using photochemical reactions.

Stereolithography, or resin printing, uses an ultraviolet laser that focuses on a vat of photopolymer resin. The 3D printers derive all the information from the CAD design, creating routes for the laser. Upon contact, the resin solidifies to form a layer of the rapid prototype.

Then, the part is submerged into resin again and the printing of another layer starts. After the process is complete, the parts must be cleaned from all the wet resin. Also, the cutting off of supportive structures for overhanging elements is necessary.

Test in the real world

Know exactly how your products will look and perform before investing in tooling. A wide range of 3D printing materials can produce tough functional prototypes for highly accurate performance testing, or realistic models that look and feel like your finished products.

Types of prototypes in product design

Prototypes can be categorised depending on the degree of accuracy required i.e. “Fidelity” or where in the product development stage it is used.

Why is rapid prototyping important?

In this fast-moving modern-day consumer market, companies need to develop and introduce new products faster to remain competitive. Since faster product development and technology innovation are key to a company’s success, rapid prototyping becomes the most important element of new product development. The following objectives are achieved through rapid prototyping.